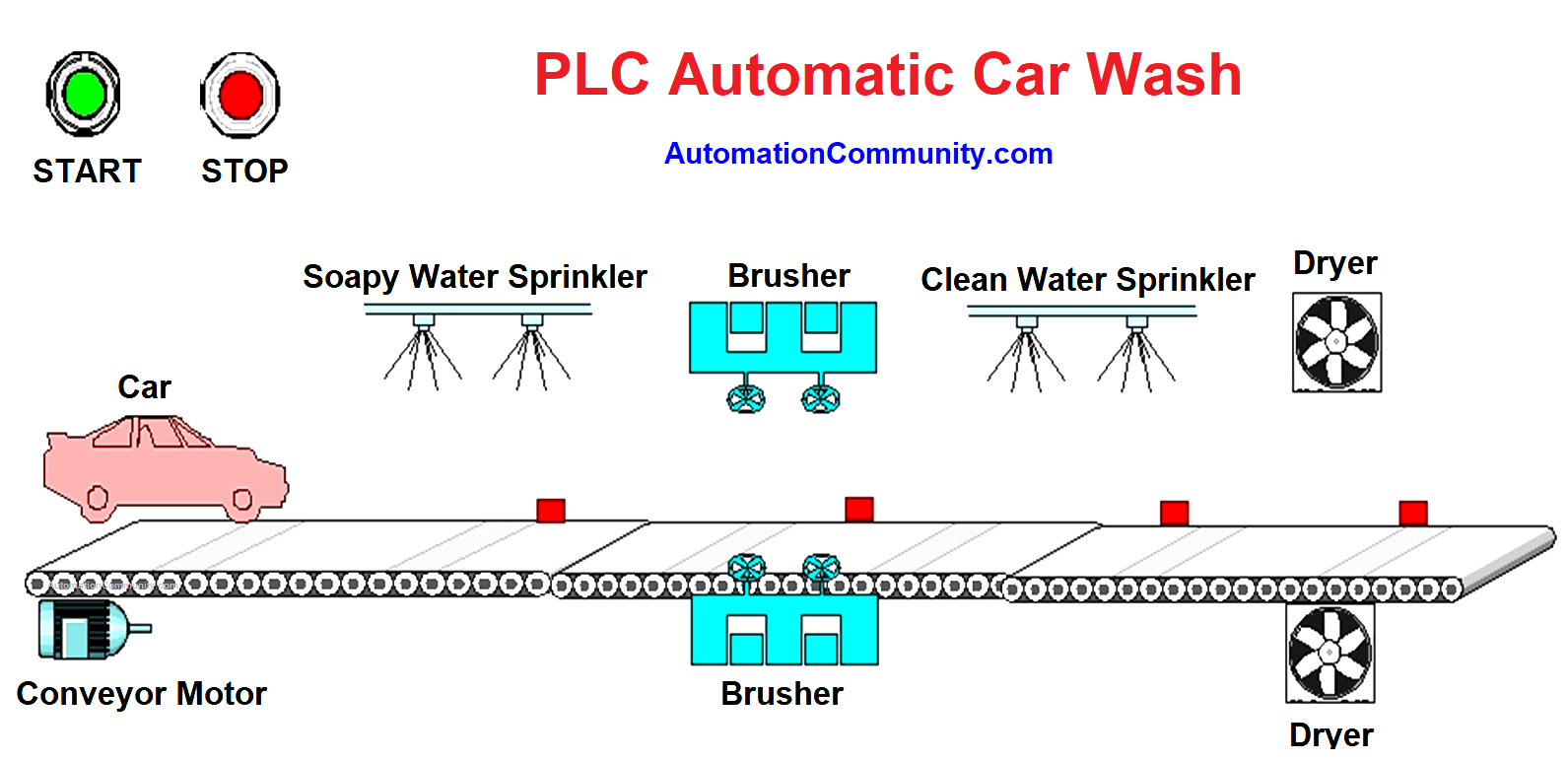

PLC Automatic Car Washing System Project

In this article, you will learn about the PLC-based automatic car washing system project using ladder logic programming and explanation.

PLC Car Washing

Problem Solution

- The car entry sensor triggers the process and turns the conveyor belt ON to move the car.

- The soapy water sprinkler turns ON when the stage 1 sensor detects the car and does the process for a certain time.

- Brusher turns ON when stage 2 sensors detect the car and do the process for a certain time.

- The clean water sprinkler turns ON when stage 3 sensors detect the car and do the process for a certain time.

- The dryer turns ON when stage 4 sensors detect the car and do the process for a certain time.

- The car exit sensor triggers the conveyor motor to turn off.

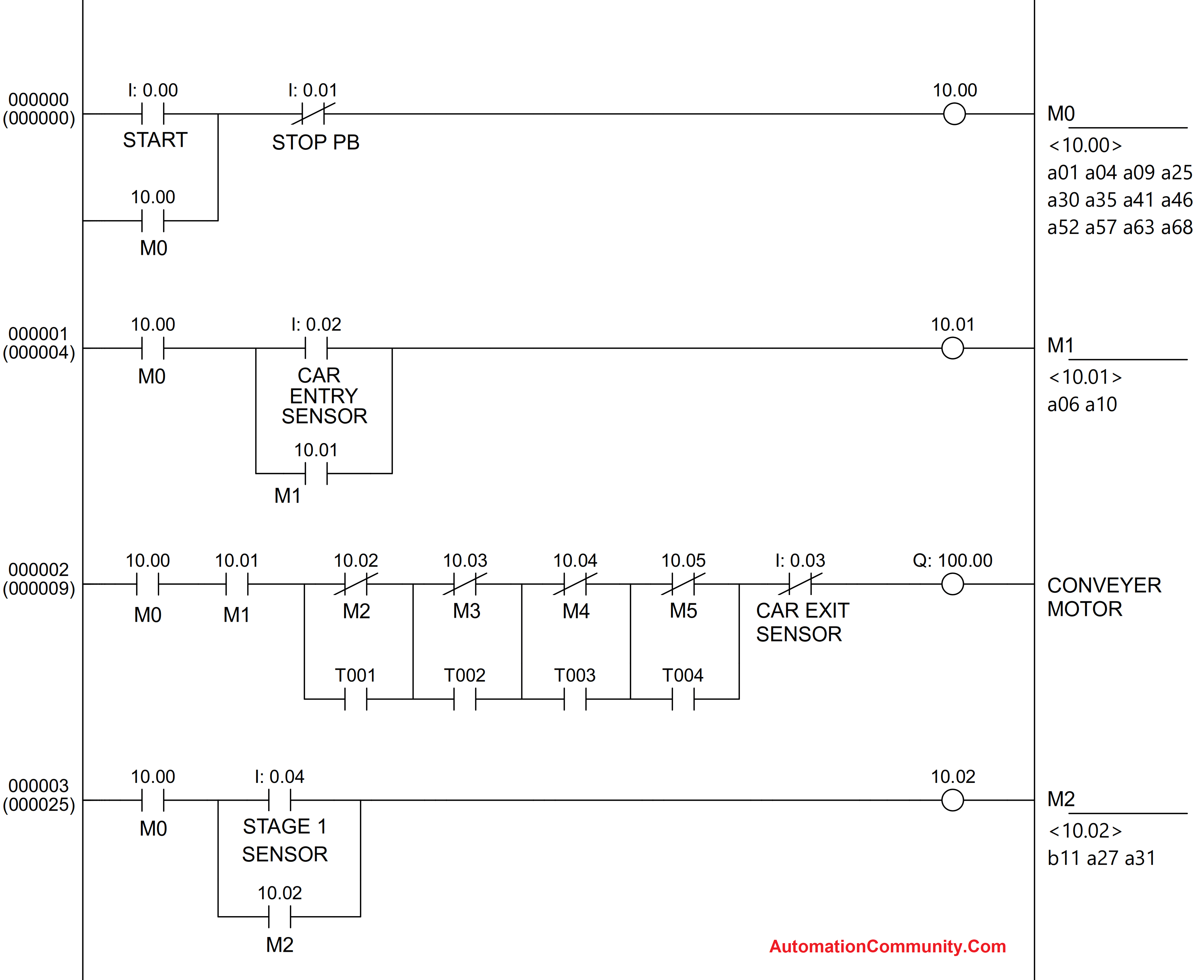

PLC Car Washing Logic

PLC Program Description

- Latching rung to operate the system through Master Start and Stop PB.

- The car entry sensor triggers the memory bit which will turn on the conveyor motor

- ON/OFF operation of conveyer motor is happening in this rung using various conditions like Sensor input and timer done output.

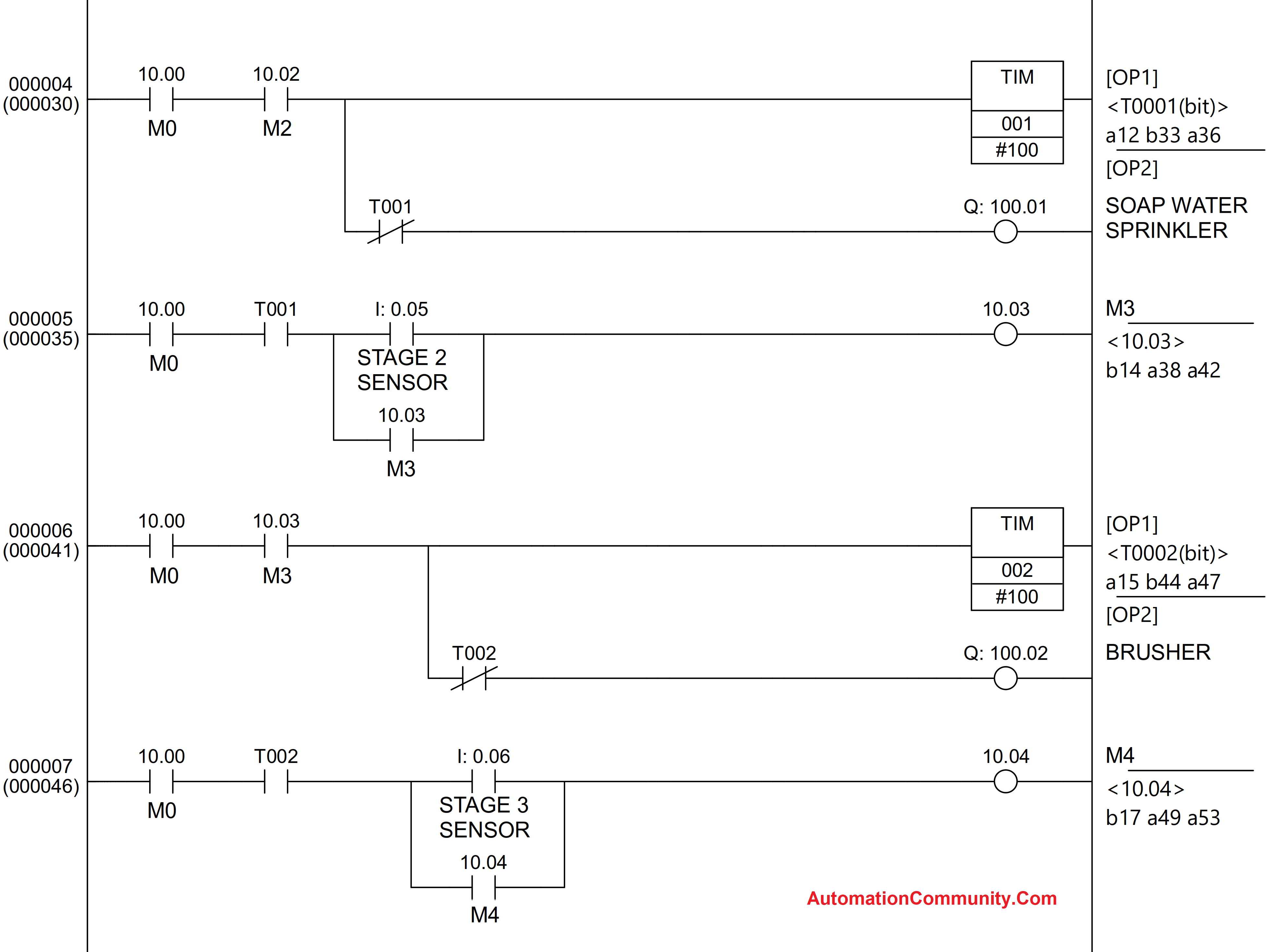

- When the car reached stage 1 sensor conveyor motor should stop and the water sprinkler should be ON for 10 sec. At the end of the water sprinkler timer, Conveyer will again be ON because of the parallel contact

- When the car reached stage 2 sensor conveyor motor should stop and the brusher should ON for 10 sec. At the end of the brushing process, Conveyer will again be ON because of the parallel contact.

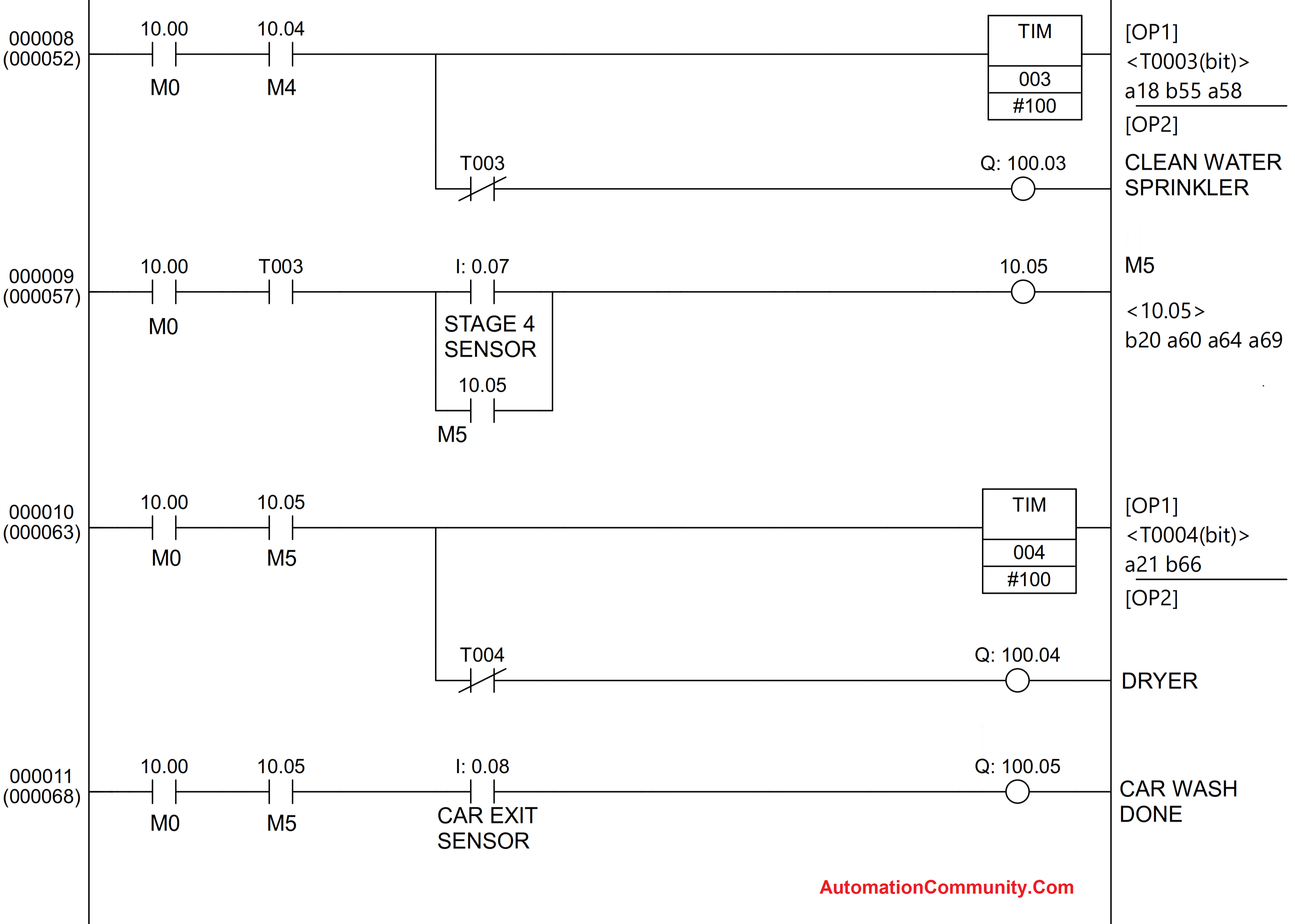

- When the car reached stage 3 sensor conveyor motor should stop and the water sprinkler should be ON for 10 sec. At the end of the water sprinkler timer, Conveyer will again be ON because of the parallel contact.

- When the car reached stage 4 sensor conveyor motor should stop and the water sprinkler should be ON for 10 sec. At the end of the water sprinkler timer, Conveyer will again be ON because of the parallel contact.

- When the car reached the exit, the car exit sensor will trigger the car wash done indication lamp.

Note: This PLC example is from the Omron PLC course.

Author: Hema

This course is very good

I want to try this on my TIA portal for siemens and Control builder software for ABB PLC

Fantastic one. I love the program, however I made two observations:

1. on network 2 and 11, address for car exit sensor must be the same to avoid conflict.

2. on PLC program description written above for number 7, Dryer should be ON for stage 4 sensor and not water sprinkler again, I noticed a repetition.

Every other things are so accurate. Thank you so much. I have just written mine on the TIA portal

Thanks for letting me register as PLC Automatic program cause.

Course is very useful

This coruse is very good

thank a lot

This is a good course

Thanks for being registered so that I can how program instruments with PLC

Very good

great example for the beginner

This is very good example, I am beginner and trying to grab the things.

Hi, im a beginner in PLC and this is very helpful.

However how about if a carwash has packages with different types of services.

Eg: Package1 consists of Soapy Water Sprinkler & Brusher

Package 2 consists of Soapy Water Sprinkler & Dryer

Package 3 consists of Soapy Water Sprinkler, Brusher & Clean Water Sprinkler

Package 4 consists of Soapy Water Sprinkler, Brusher, Clean Water Sprinkler and Dryer

How will the ladder logic be like?

Good

This course is excellent and very usefull for us

This is a very good course of study

Good

The course was very helpful and interesting.

Very impressive ,

Thanks. interesting

This is explicit but can this parameters be used in other software excluding siemens or of not how could one achieve best results?

I like join course study subject very intrested

I love this course

Love this course

This is a good course for plc beginning

Good

Good course

the course is very informative with great content.

This course in excellent 👌

Good