A Simple Counter Application in PLC

The programmable controller includes both down counters and up counters. The up counter counts from zero up to the preset count where some action takes place.

PLC Counter Example

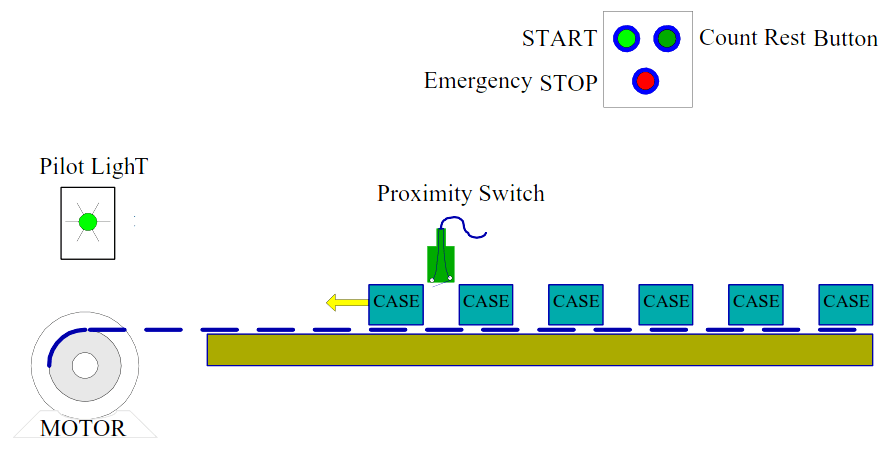

The down counter goes from a preset number down to zero where the action occurs. A conveyor motor diagram is shown in Figure illustrating the application of an up-counter.

The counter counts the number of cases coming off the conveyor. When the total number of cases reaches 10, the conveyor motor stops automatically.

A proximity switch is used to sense the passage of cases.

A Simple Counter Application

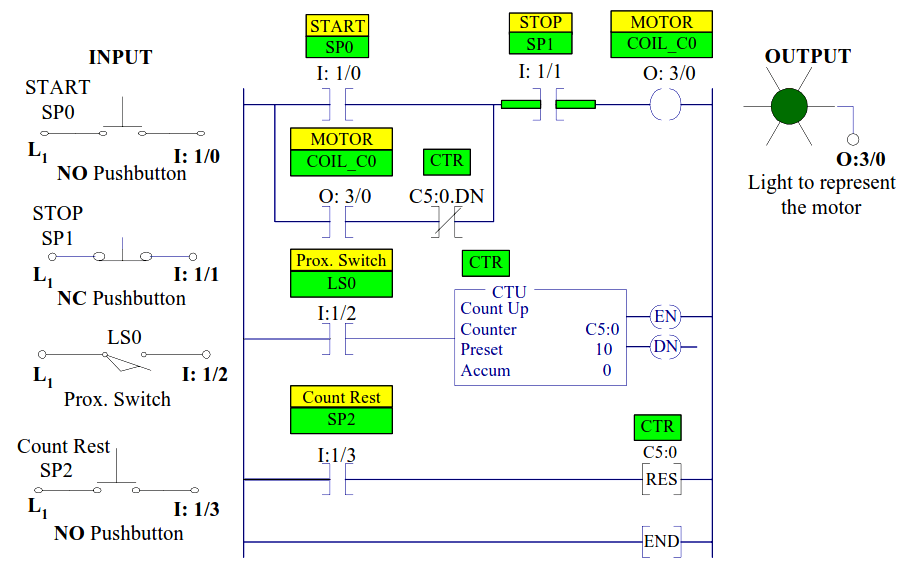

The sequential task is as follows:

1. The START button is pressed to start the conveyor motor.

2. Cases move past proximity switch and increment the counter’s accumulated value.

3. After a count of 10, the conveyor motor stops automatically and the counter’s accumulated value is reset to zero with SP2.

4. The conveyor motor can be stopped manually without loss of the accumulated count.

5. The accumulated count of the counter can be reset by means of the COUNTER RESET button.

Author: Dr. Hadi Saadat

Read Next:

perfect , good detailed explanation

replay

Excellent details

Sir,

I want knw about schneider plc programming in servo what can i do i need traing