Stop Start and Limit Switch PLC Logic

Most industrial processes require the completion of several operations to produce the required output. Manufacturing, machining, assembling, packaging, finishing, or transporting of products requires the precise coordination of tasks. The majority of industrial control processors use sequential controls. Sequential controls are required for processes that demand certain operations be performed in a specific order.

The purpose of this article is to become familiar with a few simple typical industrial applications of the PLC, such as transporting of products, controlling motor starters and sequential control systems requiring timers and counters.

Stop/Start & Limit Switch Circuit

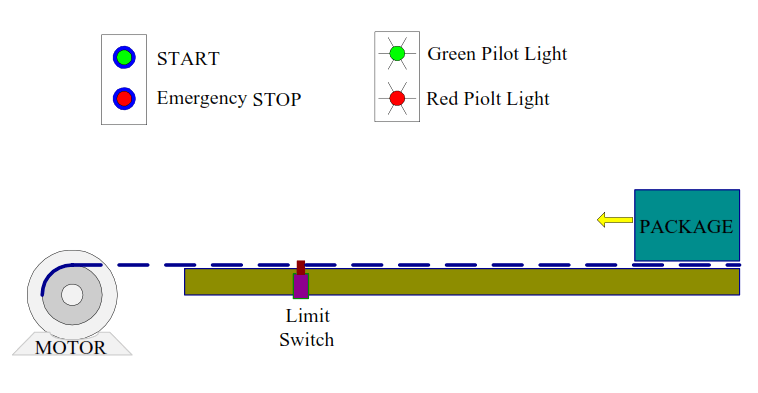

A simple process flow diagram for moving packages to a certain position is illustrated in the below Figure.

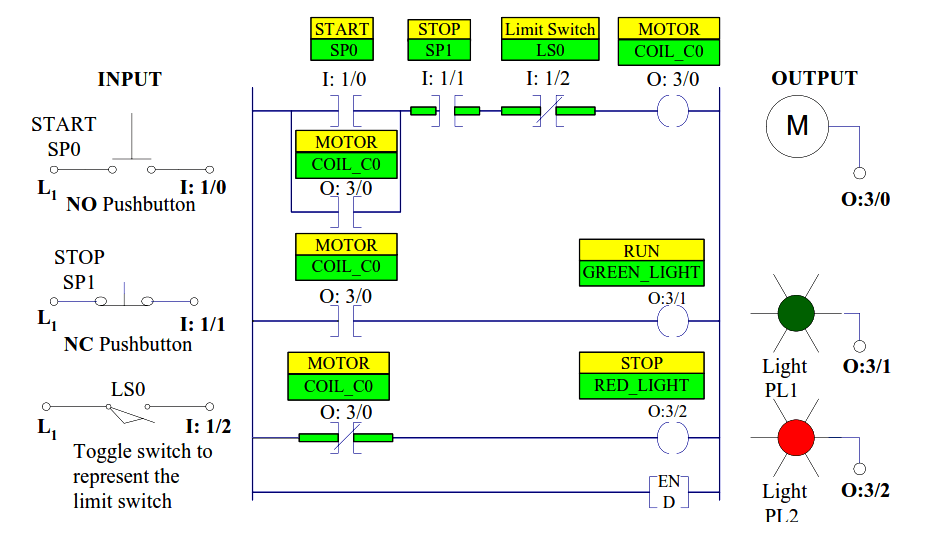

The ladder program is shown in the below Figure, it is designed for the following sequential task:

PLC Program

1. Start pushbutton is pressed.

2. The table motor is started.

3. The package moves to the position of the limit switch and stops.

4. An emergency stop pushbutton is included to stop the table for any reason before the package reaches the limit switch.

5. A red pilot light indicates the table is stopped.

6. A green pilot light indicates the table is running.

Author: Dr. Hadi Saadat

Read Next:

i need a software for s7 – 300

Hi, You can download the trial version from Siemens Website. Check Here

hi thereby did installed simatic manager package from Siemens website, but doesn’t allow me to setup.i don’t know wether is my Macbook s fault or what.may u pls help me on this

I need a full content of plc

Very good course