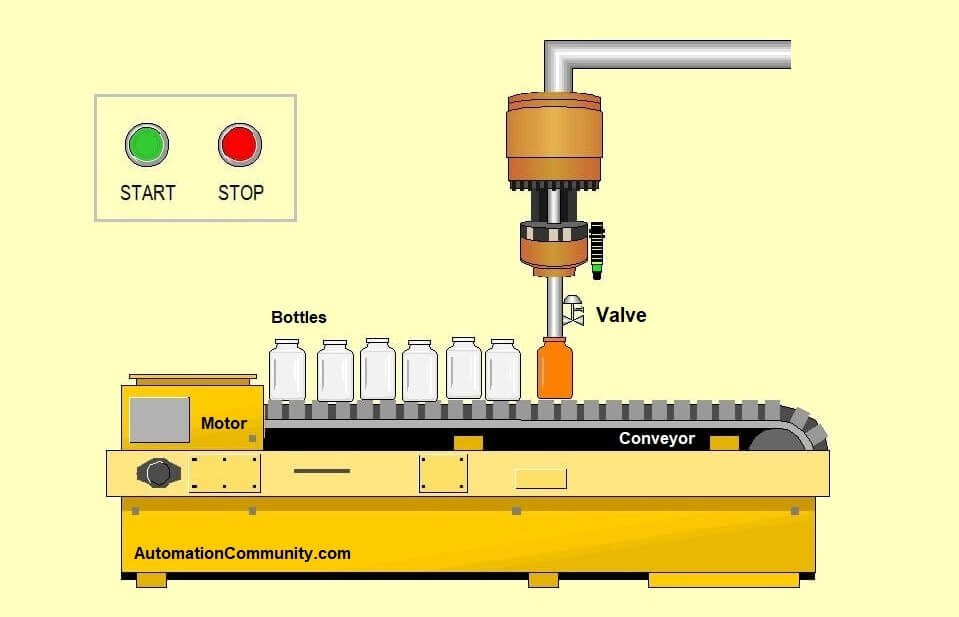

Bottle Filling PLC Ladder Logic

A bottle takes 7 seconds to be completely filled. If the filling is interrupted then the filling will resume from the same level as the liquid-filled earlier. When the filling of one bottle is completed then a motor should run for 2 seconds for changing the bottle with the next empty one.

We have a start and stop pushbuttons for controlling the bottle filling process.

Note: In this example, we are filling the bottles based on a timer (fixed time duration). You have to write the PLC logic only for the given problem. In a real-time application, there will be more safety functions and logic will be involved.

Bottle Filling PLC Ladder Logic

According to the problem, we need a valve to be open for 7 seconds, and if there is a fault in between then when the fault is resolved the timer opens the valve for the remaining time so that the bottle gets completely filled, and does not get overflow.

In order to do so, we have used a TONR that does not get reset completely even after power is cut. It needs a reset input to do so. This timer can be used to control the filling valve.

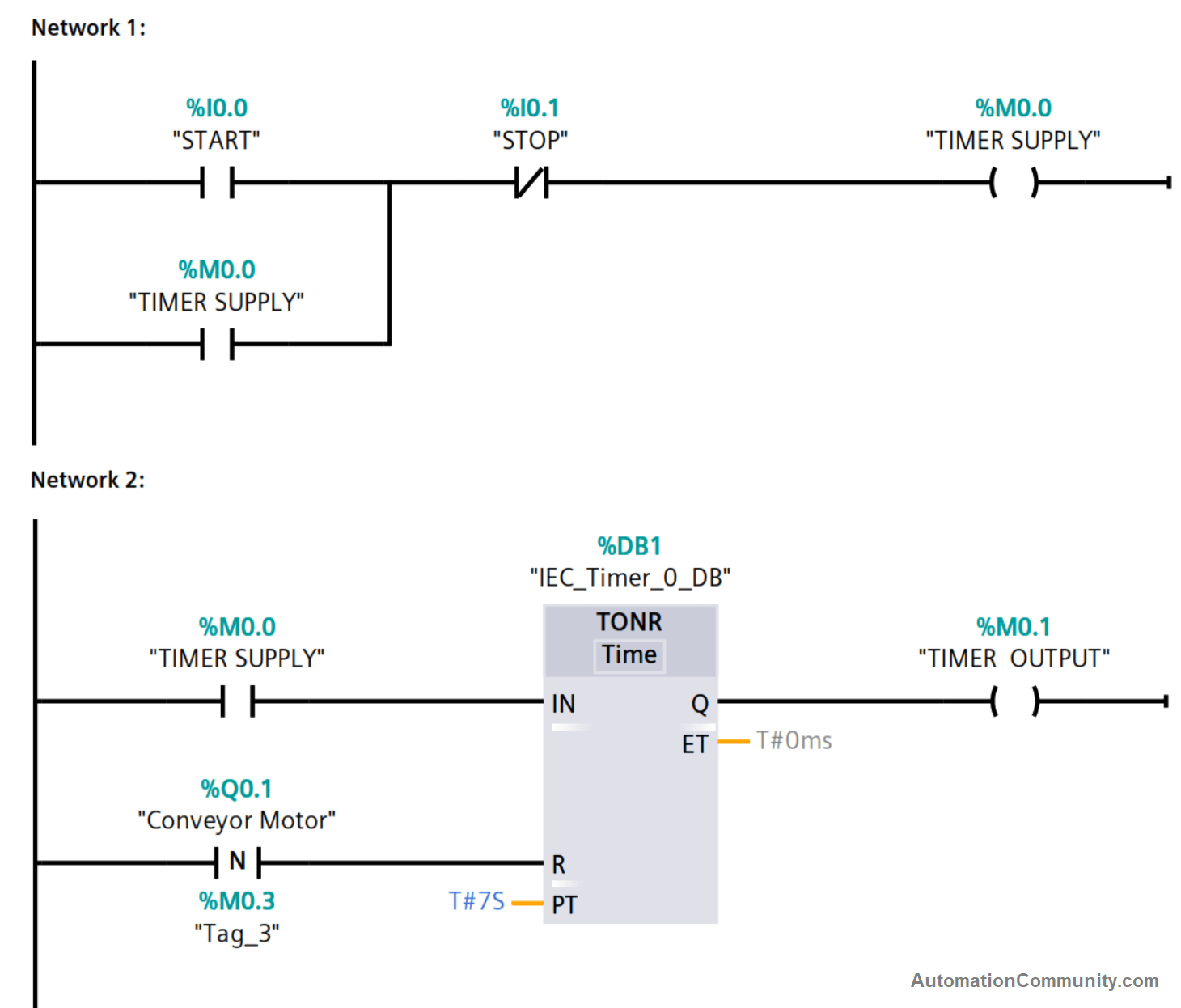

Network 1

It is a simple holding circuit that is used to control the state of the memory bit. An NO is connected in parallel to the start input with the same address as the output, which helps us to hold the circuit.

An NC is connected in series with the output to stop the ON state of the output.

Network-2:

It contains a TONR whose state is controlled by the memory bit status from network 1. As the timer is turned on the memory bit M0.1 is activated after 7 seconds.

If the supply is interrupted in between then it starts again from the time it has been covered before, so that the bottle does not overflow.

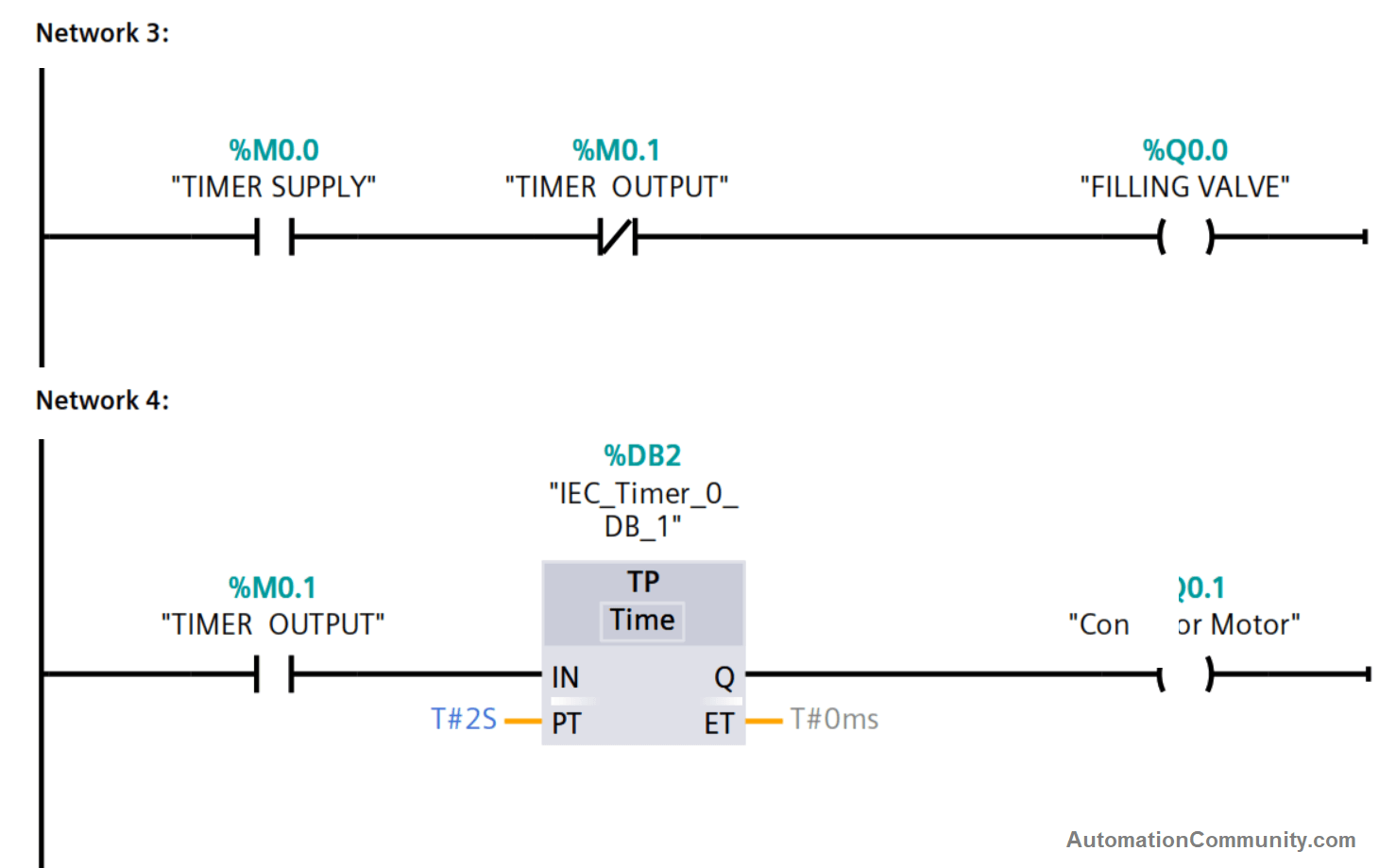

Network-3:

It is a simple interlock to control the filling valve as per the memory bit M0.1 which is in turn controlled by TONR.

As soon as the start is activated in network 1, M0.0 gets high and remains in the high state until stopped.

The fill valve will be in the open state until the timer TONR is not in the active state.

Network-4:

When the filling of the bottle is complete the conveyor motor should be turned on for 2 seconds.

To turn on the motor for 2 seconds we can use TP, after which the timer TONR is made to reset the timer TONR using the output bit Q0.1 and the process continues.

This example is from Siemens Tia Course. Register for the Course.

What does the conveyor motor do during the interrupt

Ok.

It’s informative, Thanks!

ok